The technical centre of the Research Institute of Feed Technology has its own semi-technical feed production line, where experimental investigations can be carried out under practical conditions.

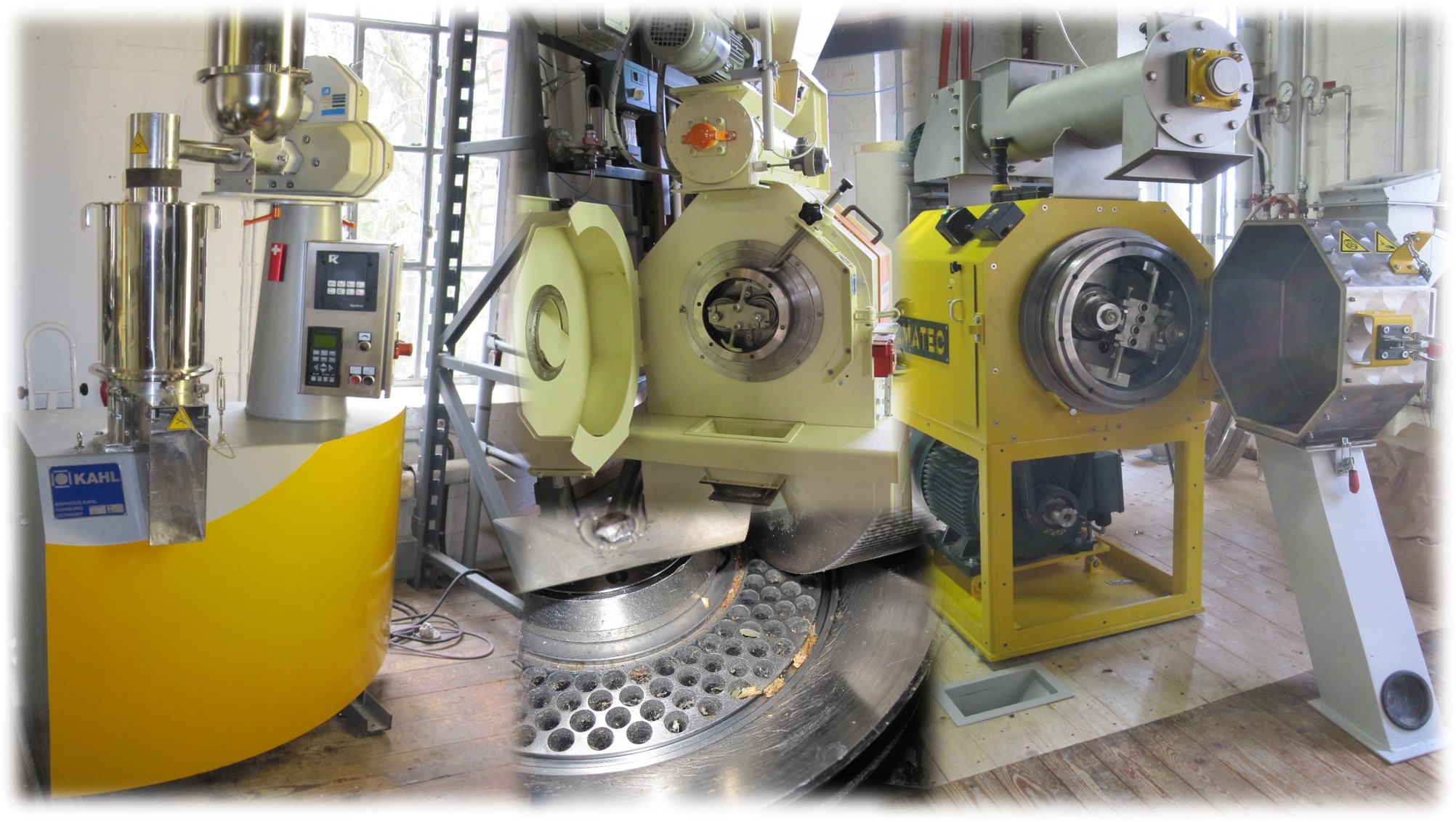

Crushing

(of mixed components or individual components)

Roller mill with transparent front wall and variable speed, gap adjustment, smooth or corrugated rollers

→ Throughput up to 400 kg/h

Hammer mill with variable speed, different sieve sizes

→ Throughput up to 1000 kg/h

Disc mill (variable speed disc mill)

Mixing

Small mixing systems

→ 2.5 to 20 litres of usable volume#

Experimental mixer with jacket heating and variable speed, various mixing tools and saturated steam direct addition

→ 25 litres useful volume

Mixer with liquid addition

→ 65 litres useful volume

Twin- shaft mixers

→ 400 litres useful volume

High-speed mixers

→ 1000 litres useful volume

In all mixing systems, the spraying of liquids is possible!

Press-agglomeration

Laboratory flat die press with various dies for very small experiments

→ Throughput approx. 50 kg/h

Ring die presses with various dies and short-term conditioning

→ Throughput 200-1000 kg/h

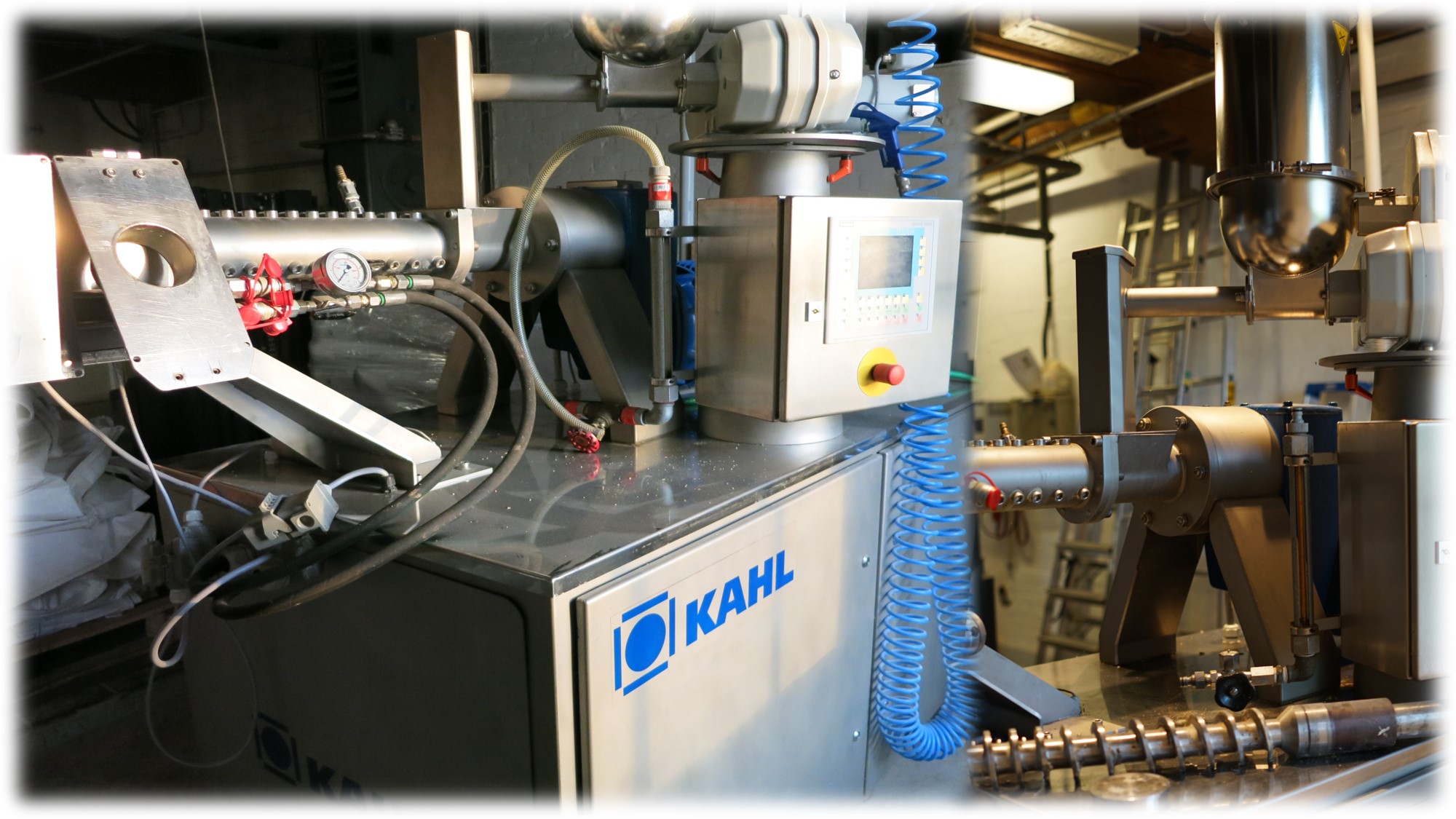

Expander

Kahl expander on a pilot plant scale

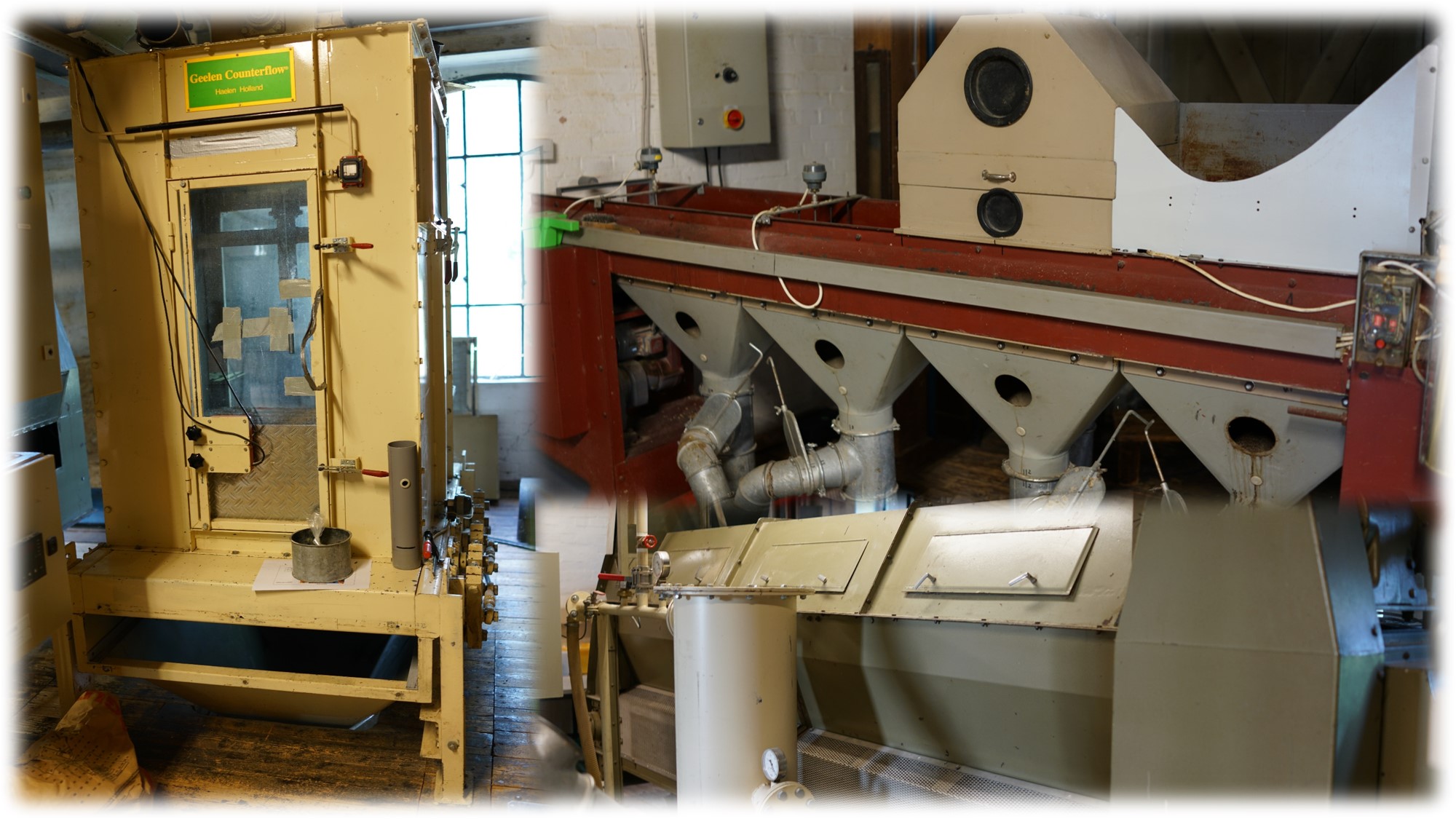

Coolers

Flow cooler

Belt cooler

Crushing

(of mixed components or individual components)

Roller mill with transparent front wall and variable speed, gap adjustment, smooth or corrugated rollers

→ Throughput up to 400 kg/h

Hammer mill with variable speed, different sieve sizes

→ Throughput up to 1000 kg/h

Disc mill (variable speed disc mill)

Mixing

Small mixing systems

→ 2.5 to 20 litres of usable volume#

Experimental mixer with jacket heating and variable speed, various mixing tools and saturated steam direct addition

→ 25 litres useful volume

Mixer with liquid addition

→ 65 litres useful volume

Twin- shaft mixers

→ 400 litres useful volume

High-speed mixers

→ 1000 litres useful volume

In all mixing systems, the spraying of liquids is possible!

Press-agglomeration

Laboratory flat die press with various dies for very small experiments

→ Throughput approx. 50 kg/h

Ring die presses with various dies and short-term conditioning

→ Throughput 200-1000 kg/h

Expander

Kahl expander on a pilot plant scale

Coolers

Flow cooler

Belt cooler

In addition, we carry out various analyses in our chemical and physical laboratories.

Pellet abrasion and hardness

Mechanical and pneumatic stress as required

mechanical: Quick-tester with rotation disk, Pfost-tester

pneumatic: Ligno-tester, Holmen-tester

Pellet hardness tester (Kahl, various versions from manual, semi-automatic to automatic)

Dusting behaviour

Palas DustView to determine dustiness and dust removal over time

Heubach Dustmeter to determine the dusting behaviour according to Pfizer (gravimetric/quanitative method)

Physical laboratory tests

Ring-shear device for determining the flowability of bulk materials

Tamping volumeter for determining the tap density

Apparatus for determining the bulk density (100 ml) according to DIN 53468

Apparatus for determining the bulk density (1 l vessel) according to DIN 1060

Helos laser-diffraction spectrometer for particle-size analysis (18-3500 μm)

Sieving machine with sieve set according to DIN 66165 and air jet sieving (32-125 μm)

Laboratory analytical methods

Photometer (measuring range 200-900 nm)

Kjeldahl distillation unit with preceding Kjeldahl digestion and subsequent titration

Drying cabinets without/with vacuum

Quick moisture analyser

Pellet abrasion and hardness

Mechanical and pneumatic stress as required

mechanical: Quick-tester with rotation disk, Pfost-tester

pneumatic: Ligno-tester, Holmen-tester

Pellet hardness tester (Kahl, various versions from manual, semi-automatic to automatic)

Dusting behaviour

Palas DustView to determine dustiness and dust removal over time

Heubach Dustmeter to determine the dusting behaviour according to Pfizer (gravimetric/quanitative method)

Physical laboratory tests

Ring-shear device for determining the flowability of bulk materials

Tamping volumeter for determining the tap density

Apparatus for determining the bulk density (100 ml) according to DIN 53468

Apparatus for determining the bulk density (1 l vessel) according to DIN 1060

Helos laser-diffraction spectrometer for particle-size analysis (18-3500 μm)

Sieving machine with sieve set according to DIN 66165 and air jet sieving (32-125 μm)